Natural gas meets more than a third of the US energy needs. With extensive pipeline networks delivering this precious commodity, proper installation is a non-negotiable, and it starts with quality trenching solutions.

Certified underground gas line installers use cutting-edge technology and industry-grade techniques to ensure you have optimum gas flow devoid of leakages, obstructions, and breakages.

Gas line installers use trenching and trenchless excavation to install gas lines. Various factors determine the ideal technique to maintain efficiency, minimize risks, and coordinate activities during the installation.

In this blog post, you will learn about the following:

- Trenching Solutions

- Open-cut Trenching

- Factors to Consider for Open-Cut Trenching

- Advantages of Open-Cut Trenching in Gas Pipeline Installation

- Trenchless Technology

- How to Enhance Trenching Efficiency

Trenching Solutions

There are two primary trenching solutions:

- Open-cut trenching

- Trenchless technology

Let’s go through each in detail to see how you can use it to install gas lines efficiently.

Open-Cut Trenching

The open-cut trench excavation is a traditional technique that involves excavating trenches to create space for placing new gas lines. It is effective in replacing or installing entire gas lines. Technicians use excavators, trenchers, backhoes, or skid steers to make sizable trenches for gas pipelines.

Although seen as an outdated solution, open-cut trenching is still common and has advantages in gas line repairs, installation, and replacement. Working with professional technicians creates a difference in the efficiency of this technique.

The open-cut method provides direct access to the site, allowing quick gas line installation and fixing.

Factors to Consider for Open-Cut Trenching

It is worth noting that not every gas line installation process qualifies for open-cut trench excavation. Contractors consider several factors before opting for this trenching solution.

1. Type of Ground

Open-cut trenching is ideal for non-paved areas like yards because the excavation process is much more seamless. There is no need to break concrete or asphalt, remove and reinstall pavement, or do temporary constructions. Once the installation process is complete, technicians backfill the trench and restore surface vegetation with seed or sod.

2. Large Scale Installation Projects

The open-cut technique is ideal for large-scale gas pipeline installation projects with ample space because the landmass can accommodate heavy machinery like trenchers, quickening the excavation process when operating at maximum capacity. The extra space also allows for equipment and material organization and workforce movement.

3. Trench Size

The standard trenching machines can only dig shallow trenches. Local building codes require gas lines to be 24 inches to 36 inches deep in the ground to prevent temperature fluctuations and damage risks from activities such as gardening, landscaping, or erosion.

Open cut-trenching can achieve this requirement depending on the machinery used. Excavators and trenchers can produce sizable, consistent trenches ideal for underground gas lines.

An advantage of shallow trenches is that they require minimal trench wall support compared to deep trenches. Their stability eliminates the need for shoring systems to support the walls.

4. Soil Condition

It is impossible to excavate trenches without stable soil. The soil’s stability directly impacts the risk of cave-ins and shifts in the trench. The open-cut method requires stable soils because of their predictable behavior. The risk of cave-ins or shifts is also lower.

5. Property Layout

Minimizing accidents on site is a top priority when making trenches. Open-cut trenches require ample space for organization and efficient use of the excavation area with minimal disruption of adjacent properties. Strict safety measures are crucial during excavation to reduce accidental risks and property destruction.

6. Affordability

Open-cut trenching solutions are more affordable because of their minimal requirements. Qualifying homeowners do not have to grapple with additional procedures before, during, and after their gas line installation.

Advantages of Open-Cut Trenching in Gas Pipeline Installation

Open trenches offer easy access for the entire length of the gas line during installation, simplifying pipe laying, welding, and inspection. Additionally, future maintenance or repairs become easier with direct access to the line for troubleshooting and intervention.

The open-cut technique also eliminates additional steps necessary in trenchless solutions like pilot holes, shoring, or drilling, making it straightforward and cost-effective. The simple installation process requires minimal specialized equipment and complex methodologies.

Trenchless Technology

Trenchless gas line installation is an ideal solution for properties with paved spaces, unstable soil, underground utilities, or close proximity to other properties. The technology has a variety of options.

1. Horizontal Directional Drilling (HDD)

Directional boring or HDD uses a directional drilling machine and its attachments to drill underground along the chosen path and backream the required gas pipe. It is ideal for properties with numerous obstacles or hard terrain, making open-cut trenching impossible. Excavation areas with pavement, buildings, or other infrastructures also benefit from this technique because it is minimally invasive.

It works well with unstable soil or in long-distance gas pipeline installation. Most importantly, if you want to preserve the integrity of your land, this minimally invasive trenchless technology works. The entire process occurs in three steps:

Step 1: Pilot Drilling

The technicians drill a small pilot hole and then pump drilling fluid in the drill pipe to the drill bit. Next, they use high-pressure jets to grind the soil as the fluid transports cuttings to the entrance pit.

Step 2: Pre-Reaming

The second stage entails enlarging the size of the pilot hole to install the gas line using a reamer and drilling fluid to smoothen the hole.

Step 3: Pipe Pullback

The last stage entails pulling the gas pipe into the drill hole.

2. Microtunneling

For underground gas lines with narrow diameters, microtunneling is the perfect solution. Installation begins with drilling entry and exit shafts on the gas pipeline route. The pipes are then introduced into the shafts and pushed forward using hydraulic jacks.

Microtunneling has high accuracy rates because of its laser guidance and constant monitoring system. It also has minimal surface disruption compared to open-cut trenching.

Furthermore, it minimizes workforce risks as the excavation is not labor intensive. Additionally, the non-invasive technique is suitable for a variety of soils. However, the diameter limitations can be impractical for operations.

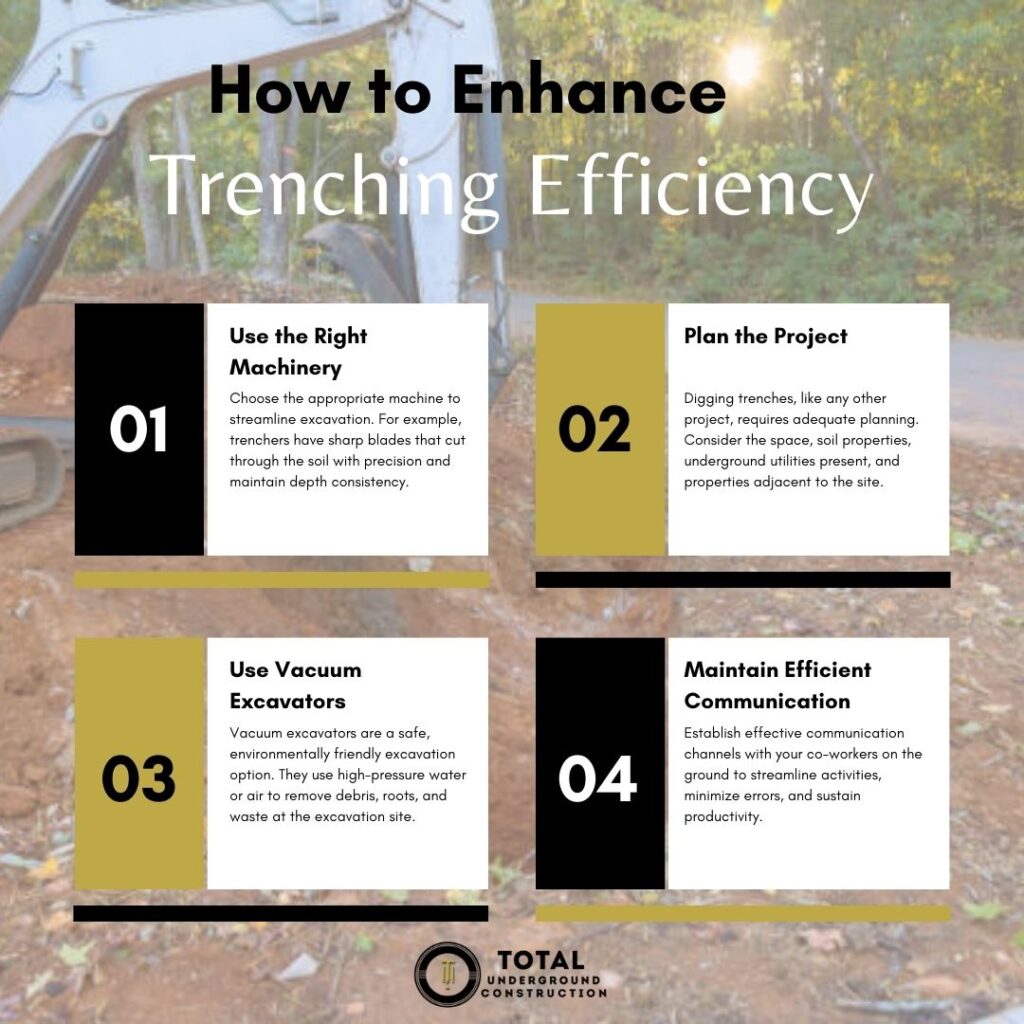

How to Enhance Trenching Efficiency

Despite the technique used, some factors can influence the functionality of the tunnel. These include the machinery, plan, type of excavator, and communication.

1. Use the Right Machinery

Choose the appropriate machine to streamline excavation. Industry-grade trenchers have sharp blades that cut through the soil with precision and maintain depth consistency.

Excavators are versatile in terms of the variety of length and width they can achieve. On the other hand, backhoes are efficient for digging shallow trenches in confined spaces.

2. Plan the Project

Digging trenches, like any other project, requires adequate planning. Consider the space, soil properties, underground utilities present, and properties adjacent to the site.

Choose the right machinery according to your findings. Remember to have hazard signs and markers to guide excavation and prevent accidents.

3. Use Vacuum Excavators

Vacuum excavators are a safe, environmentally friendly excavation option. They use high-pressure water or air to remove debris, roots, and waste at the excavation site.

The machinery comes in various sizes and shapes, each capable of breaking ground, loosening the soil, and removing debris into a disposal tank.

4. Maintain Efficient Communication

Establish effective communication channels with your co-workers on the ground to streamline activities, minimize errors, and sustain productivity.

Schedule Your Underground Gas Line Installation Today

The road to secure underground gas pipelines begins with us. As the top underground construction company, we are always ready to install, assess, and maintain gas lines, ensuring they operate optimally. Call us today to schedule your appointment.