Polyvinyl chloride (PVC) is the most preferred material for indoor plumbing. According to a survey by Accountability Information Management, Inc. (AIM), 64% of respondents prefer PVC pipes for potable water systems, 77% approve it for wastewater pipelines, and 66% laud it for drain, vent, or waste pipes.

Over 65% of new installations and replacements are PVC pipes because of the material’s efficiency, durability, long-term performance, low corrosive rates, and ease of installation and repair.

Despite their advantages, PVC pipes are not immune to cracks and fissures. Without prompt repairs, they can cause multiple issues. At Total Underground Construction, we provide cracked PVC pipe repair. Call us for quick, quality, and affordable fixes.

Table of Content:

- Causes of PVC Pipe Fractures

- Repair Your Cracked PVC Pipe Like a Pro

- Let The Real Pros Handle Your Fractured PVC Pipe

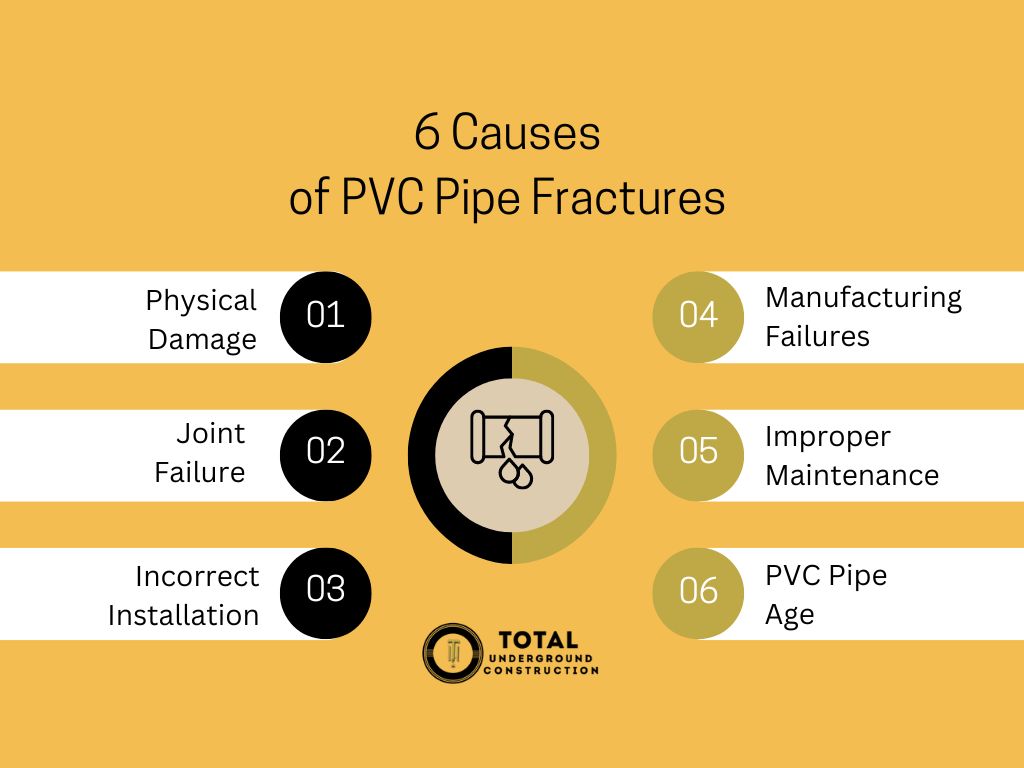

Causes of PVC Pipe Fractures

PVC pipes are sturdy and durable, lasting up to ten years without any issues with proper maintenance. Nevertheless, the material is still susceptible to cracks, and several conditions weaken its structural integrity.

1. Physical Damage

PVC is a type of plastic that can crack or break under high impact. The damage risk depends on the pipe’s:

- Location Size

- Wall thickness

- PVC formulation

Larger-diameter pipes can withstand higher forces than their smaller counterparts. Similarly, exposed pipes under the sink or running doors are more susceptible to breakage than underground pipes.

Pipelines with thick walls are more resistant to impact force than thin PVC pipes. High-impact pipes also have formulations that increase their resistance to force. The type of force or position of impact also increases the risk of physical damage. For instance, accidental drops can produce brittle fractures. Fracture risk increases if the fall impact is in the middle of the pipe.

2. Joint Failure

A joint is the weakest part of a PVC pipe and, most of the time, the cause of a fracture. Large-diameter PVC pipes have spigot-bell joints. At the end of one pipe is a bell with a rubber gasket that securely adjoins the spigot end of an adjacent pipe without any contact. Inserting the spigot and bell ends is a delicate procedure that can create defects in the PVC pipe.

For instance, the bell can split if it comes in direct contact with the fixture because the insertion is too far – an issue called over-belling. You need a PVC forensic expert to determine if the problem occurred during installation or due to failure.

3. Incorrect Installation

One way to maintain the structural integrity of a PVC pipeline is professional installation. Installation mishaps eventually lead to costly replacements and repairs. Applying too much cement to seal gaps between the pipe and its fitting can cause improper fusion, creating cracks. On the other hand, insufficient cement creates voids in the joints.

Another installation issue is using the wrong solvent weld to boost fusion between the pipe and fitting. This interferes with the fusion process, forming voids that interfere with the conduit’s functioning.

4. Manufacturing Failures

Manufacturers use an extrusion process to produce PVC pipes. The process entails melting PVC powder and propelling it through a highly pressurized circular die for knitting. At the die face’s center, a solid metal plug secured by thin metallic vanes is.

The vanes function like blades, slicing the molten plastic flowing through the die’s circular channels. As the plastic exists, it rejoins and cools into a solid PVC pipe wall.

Occasionally, the plastic may not fully fuse during the extrusion process, producing weak spots known as knit lines. The compromised areas have the least resistance in the pipeline’s structure. It split longitudinally, running throughout the entire pipe length.

Pipe fractures at knit lines curl up with the edge of the splits overlapping. The risk of such fractures increases when manufacturers use high residual stress on the walls of the PVC pipes during production.

5. Improper Maintenance

As with all plumbing systems, care should be proactive in PVC pipelines. However, most underground PVC pipes are bought, installed, and forgotten without accounting for air relief and surge control maintenance. While quality PVC pipes can remain sturdy with some neglect, you severely reduce their lifespan without proper maintenance.

Professional plumbers account for burial depth during installation. However, maintenance ensures the pipes retain structural integrity as the ground and water pressure variations strain the PVC pipe walls. Remember, these pressure surges occur frequently inside underground piping systems.

Plumbers must account for the nature of the ground. Will the pipes lie under a high-traffic area above the ground? Is the ground underneath rocky or sandy? Ground shifts to wetness or dryness caused by hot and cold weather patterns cause pressure changes underground that can tamper with the structural integrity of the PVC pipe. Additionally, increased water pressure inside the pipe adds stress to the pipe structure, increasing the risk of fractures.

Professional plumbers account for burial depth during installation. However, maintenance ensures the pipes retain structural integrity as the ground and water pressure variations strain the PVC pipe walls. Remember, these pressure surges occur frequently inside underground piping systems.

Plumbers must account for the nature of the ground. Will the pipes lie under a high-traffic area above the ground? Is the ground underneath rocky or sandy? Ground shifts to wetness or dryness caused by hot and cold weather patterns cause pressure changes underground that can tamper with the structural integrity of the PVC pipe. Additionally, increased water pressure inside the pipe adds stress to the pipe structure, increasing the risk of fractures.

6. PVC Pipe Age

An old PVC pipe is more vulnerable to fractures because it has been exposed to elements like water, geospatial pressure changes, and temperature fluctuations for long periods. Old pipes gradually stiffen, becoming brittle and susceptible to fractures.

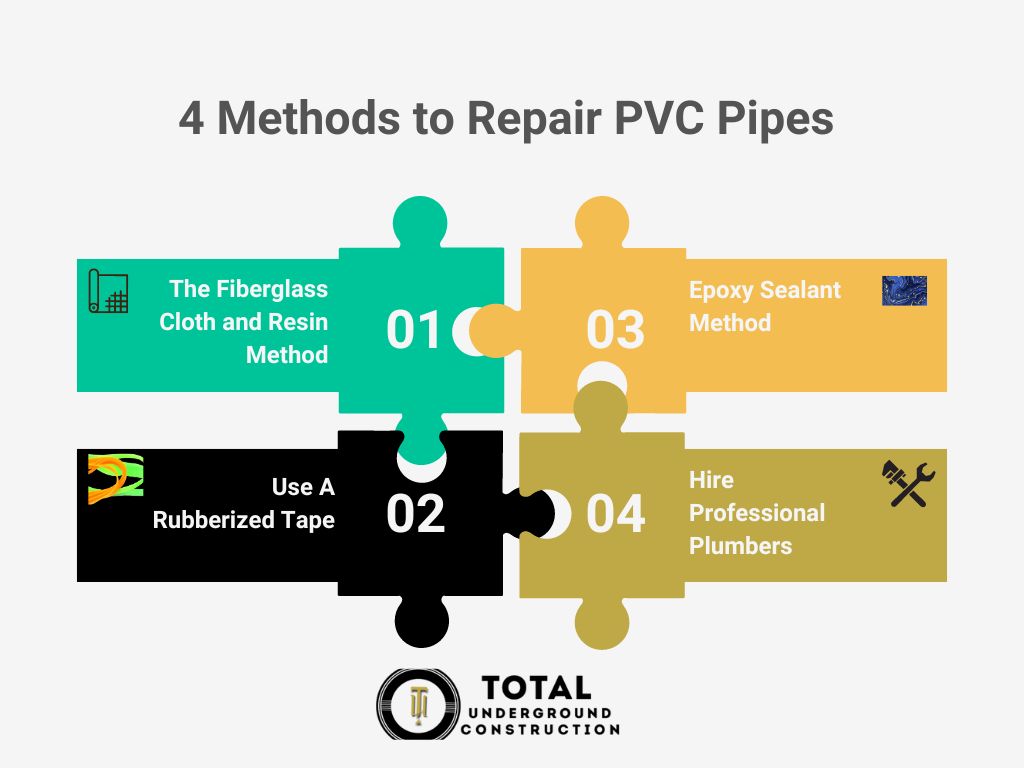

Repair Your Cracked PVC Pipe Like a Pro

If you suspect your PVC pipe has a crack, it probably does. Here are tried-and-tested ways to fix the problem before it gets out of hand.

1. The Fiberglass Cloth and Resin Method

Once you locate the crack in your pipe, apply a fiberglass cloth and water-activated resin. The fiberglass cloth has thin glass fibers that bind to the water-activated resin to strengthen and reinforce the rigidity of the cracked pipe.

2. Epoxy Sealant Method

You can also use epoxy to restore your fractured PVC pipe temporarily. Epoxy is a waterproof sealant that molds to the pipe, securing the fissure until a professional plumber can fix the problem.

3. Use A Rubberized Tape

Another temporary solution is wrapping a rubberized tape around the pipe fracture. The tape uses compression to stop the leak. Ensure the tape fits the pipe for effective water loss mitigation.

4. Hire Professional Plumbers

DIY PVC fracture repairs offer temporary relief. Eventually, you will need a plumber with expertise in handling PVC pipes to fix the fracture. Here are the steps we use to repair cracked PVC pipes:

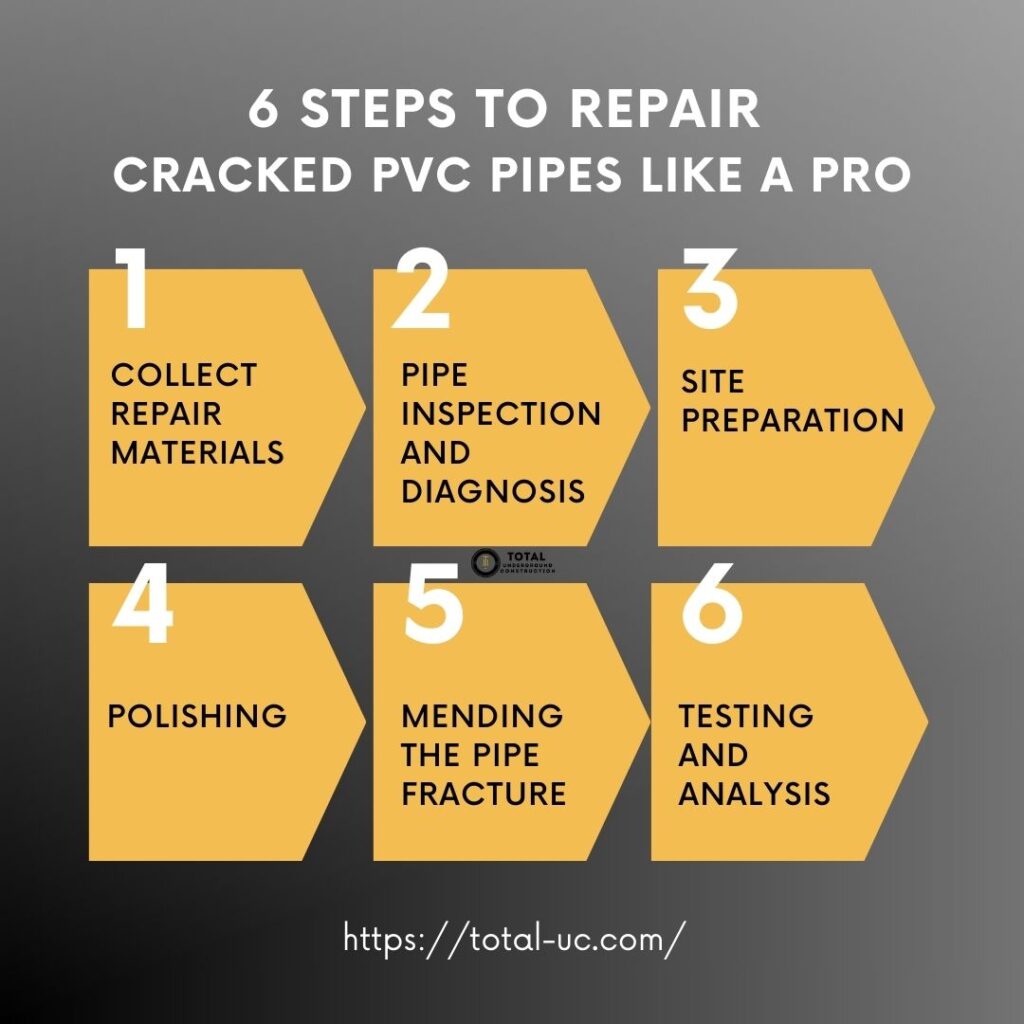

Step 1: Collect Repair Materials

- Sanitizing agent

- PVC cement

- Sandpaper

- PVC primer

- PVC pipe pieces for replacement

Step 2: Pipe Inspection and Diagnosis

Professional plumbers begin the process by assessing the PVC pipe’s age, crack size and intensity, and causation to develop a comprehensive diagnosis. Knowing the cause of the fracture is essential. It informs the mitigation strategy that effectively resolves the problem in the long term.

If your PVC pipe is old, an entire replacement may be necessary. The same applies to manufacturing defects. Point force and pressure cracks may require localized repairs, depending on the magnitude of the fracture created.

Step 3: Site Preparation

Chances are the compromised area has an infiltration of impurities, from mold growth to slurry buildup. Professional plumbers clean the site, removing fungi, algae, and debris using a sanitizing agent. Impurities also interfere with binding the fracture. Therefore, a professional cleanup is essential.

Step 4: Polishing

The plumber polishes the fracture once the site is clean to ensure seamless bonding. Fractures have ragged edges from the tears that may create voids during the joining process. The plumber uses sandpaper to polish the crack and clear the resulting dust.

Step 5: Mending The Pipe Fracture

The type of material used to repair the cracked PVC pipe depends on its magnitude. A renowned go-to method for permanent sealing is the PVC cement and primer method. The primer cleans the surface while the cement holds the pipe together and strengthens the pipe structure. This method is effective for low-pressure plumbing systems like drain lines.

Extensive fractures or cracks in old PVC pipes may require portion replacements. In a standard cut-and-replace method, the plumber digs the pipe to access the crack, cuts the compromised area, and replaces it with a new pipe section using the cement and primer method.

Another trench replacement method that involves less digging is the slip coupling repair. The plumber cuts a short section of the damaged pipe and slides a specially designed coupling over the existing pipe on both ends. They then insert a new pipe piece into each coupling end and secure the area with PVC cement.

Trenchless repairs include the pipe-bursting technique, where the technician inserts a head burst into the fractured PVC, which expands, breaking the old pipe. Using the head burst, the plumber adds a new high-density polyethylene (HDPE) into the created cavity. The cured-in-place pipe lining (CIPP) is also an effective minimal excavation repair method for broken PVC pipes.

Step 6: Testing and Analysis

Once the repair is complete and cured, plumbers usually perform tests to ascertain the plumbing system’s efficiency. We test the water flow rate, analyze for sounds, and perform other tests on the repair site. Once everything is working, the plumber will clean up the site.

Let’s Handle Your Fractured PVC Pipe

The best way to repair your cracked PVC pipe is to hire a licensed, insured, and bonded plumbing company to handle the job. At Total UC, we offer quality, professional, and reliable PVC repair services at affordable rates. Call us today for business.