Underground fire line services play a critical role in protecting buildings from fire hazards. By ensuring a reliable water supply to sprinkler systems and hydrants, these services are essential for residential and commercial properties. This guide explores how underground fire line services contribute to building safety and compliance with local fire codes.

Table of Contents

- What Are Underground Fire Line Services?

- The Role of Underground Fire Line Services in Building Safety

- Key Components of Underground Fire Line Systems

- Installation and Maintenance Best Practices

- Unique Insights: Why Choose Professional Fire Line Services

- FAQs About Underground Fire Line Services

What Are Underground Fire Line Services?

Underground fire line services refer to the inspection, installation, repair, and maintenance of underground piping that supplies water to the fire suppression systems.

Still on the fire line services overview, the services entail hydrant testing, flow testing, and fire emergency response.

Underground fire line services are essential in promoting fire safety at home and in the workplace. They protect the building from fire damage and people from injuries and loss of life. They also improve public safety by creating safer surroundings for everyone. Apart from that, their contribution prevents costly financial losses.

Fire line service providers install reliable underground fire line systems, such as fire alarm systems and fire hydrants, which improve safety. They also ensure critical sprinkler components, like pipes, valves, and hydrants, are up to standard. These professional services ensure that fire safety infrastructure, such as fire exits and extinguishers, adhere to the local fire codes.

The Role of Underground Fire Line Services in Building Safety

Underground fire line services ensure an immediate, steady water supply to fight fire. During installation, the pipes are connected to the storage tank, water main, or any other source to supply water directly to sprinkler heads and hydrant systems.

Underground fire line services minimize fire-related damage to commercial and residential property by guaranteeing a reliable fire-water supply. Thus, they ensure the sprinkler systems can automatically activate upon detecting signs of a potential fire breakout, such as elevated temperature.

These services boost occupant safety by ensuring adequate fire warning and suppression systems. The systems also prompt swift response and safe evacuation during a fire incident, keeping everyone safe. Other fire line safety benefits include minimal business disruption during a fire incident and peace of mind, as you won’t have to worry about financial losses from the fire.

Remember, most insurance companies require policyholders to perform an underground fire line inspection to obtain fire insurance. So, it is advisable to work with a professional underground fire line service to meet the necessary building fire protection regulations.

Key Components of Underground Fire Line Systems

Below are the key components of underground fire main systems and their functions.

1. Fire Hydrant

A fire hydrant is a connection point that offers ready access to water to combat fires. This underground fitting is connected to the main water supply, which could be a storage tank, a municipal water connection, or any other source.

Fire hydrants supply water for fighting fires, cleaning the streets or sewers, and construction work. They are easily distinguishable by firefighters as they are primarily bright red, though some are green.

Fire hydrants are also available in two types.

- Wet fire hydrants: This is the best type for environments with no freezing issues and where the water supply is close to the ground surface.

- Dry fire hydrants: These fire hydrants are ideal for surroundings with freezing issues and where the water is deep into the ground.

A fire hydrant consists of several components, and here’s a table breakdown:

| Hydrant Component | Description |

| Hydrant outlets | Offer water access. |

| Monitor | Mounted on top of the hydrant to offer a high-power water stream. |

| Check valves | Prevent water from moving in unintended directions. |

| Nozzle | This is where you attach the fire hose. |

| Nozzle caps | Shield the nozzle from debris and dirt. |

| Standpipe | An outdoor connection for the fire hose |

| Hose reel | A portable hose that attaches to the nozzle outlet |

2. Mains

The mains conduct water from the supply source to the sprinkler heads or hydrant system. They are made with ductile iron, PVC, cast iron, or corrosion-resistant steel.

3. Valves

An underground fire line system features different types of valves. The table below shows the common ones.

| Valve | Description |

| Stop valve (often red) | Stops water from entering the sprinkler system when the sprinkler fails |

| Control valve | Controls water flow in the sprinkler |

| Alarm valve | Open up to allow water into the alarm line (which is where the alarm bet connects) |

| Alarm check valve | Tests the sprinkler when the facility is off |

4. Sprinkler heads

Sprinkler heads are heat-sensitive valves that open to spray water when the heat suddenly rises. Inbuilt sensors start their action upon a fire signal and discharge water to douse the fire. Apart from heat-sensitive sensors, sprinkler heads have a deflector, nozzle, and sealing mechanism.

5. Other Underground Fire Line Components

Besides the mains, sprinkler heads, fire hydrants, and valves, here are other key fire line components.

- Alarm system: Upon installation, the alarm system alerts you and the local fire department when a fire is detected. It signals you to call for emergency support in case of a fire burst.

- Pressure gauge: The pressure gauge measures the water pressure.

- Pressure switch: The device puts off the fire alarm when the sprinkler head is activated and notifies the authorities when the pressure drops.

Installation and Maintenance Best Practices

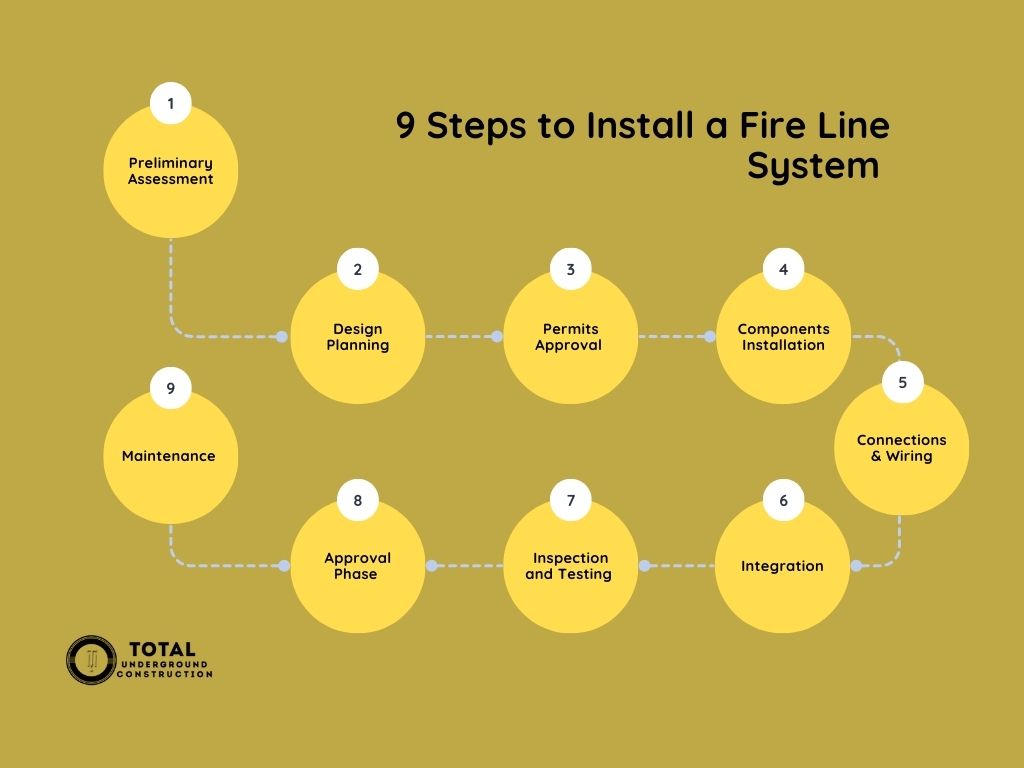

It’s essential to install a fire line system correctly in compliance with local building and fire safety codes. Thus, it’s best to consult an expert underground fire line service. Here are the key fire line installation steps and maintenance practices.

Step 1 – Preliminary Assessment

The preliminary assessment phase starts by checking the building’s layout and assessing potential fire hazards. It also includes determining a suitable sprinkler system and sprinkler spacing and positioning. In this case, you’ve to engage a fire protection expert.

Step 2 – Design Planning

During the design planning phase, a fire protection expert helps you to create a custom fire protection design plan based on the preliminary assessment. The goal is to ensure the fire line system matches your needs as the client.

Step 3 – Permits Approval

The relevant authorities must approve the firefighting design plans before trenching or installation occurs. In this case, you’ll need to request an inspection from a local fire inspector and obtain the relevant permits. While at it, comply with all fire safety standards and building codes.

Step 4 – Components Installation

The component installation phase starts with trenching and pipe layering. Here, the experts dig trenches to lay the pipes for the sprinkler system or fire hydrant according to the approved standards. Trenches act as conduits for the pipes, making the pipe placement seamless. They are sufficiently deep to allow enough cover above the pipes.

The next installation after the pipes are the sprinkler heads. The expert will mount them to the specified locations while observing the correct spacing.

Step 5 – Connections & Wiring

This phase involves connecting the water supply to the sprinkler head. If needed, the fire line safety expert may recommend installing a fire pump to increase the water pressure at the source and distribute water to try to contain a fire.

The other connection involves the wiring. In this case, the fire protection engineer ensures that the electrical components, including the fire alarm, are correctly connected to the main control panel.

Step 6 – Integration

With modern technology drawing an interest in firefighting, this phase involves integrating the fire line system with the building’s other systems, including the security stem and HVAC.

Step 7 – Inspection and Testing

To ensure the fire line system is reliable during a fire incident, it’s necessary to test it, and an expert in fire protection can help you. It’s equally important to inspect the pipes for damages and leaks. What’s more, the expert will help you conduct flow and tamper switch tests at least semiannually to prevent false alarms.

Fire line inspections ensure the system is working efficiently and reliably. They also enable you to observe compliance and identify and address risks. Ultimately, such practices foster a culture of safety first.

Step 8 – Approval Phase

In this phase, you must schedule an inspection with a locally approved fire marshal and obtain the necessary compliance certification.

Step 9 – Maintenance

Keeping the fire line system operational is paramount even after installation and approval. It’s also advisable to check for repairs and fix them in time. Thus, you should schedule periodic inspections and testing by an expert in maintenance for fire line systems.

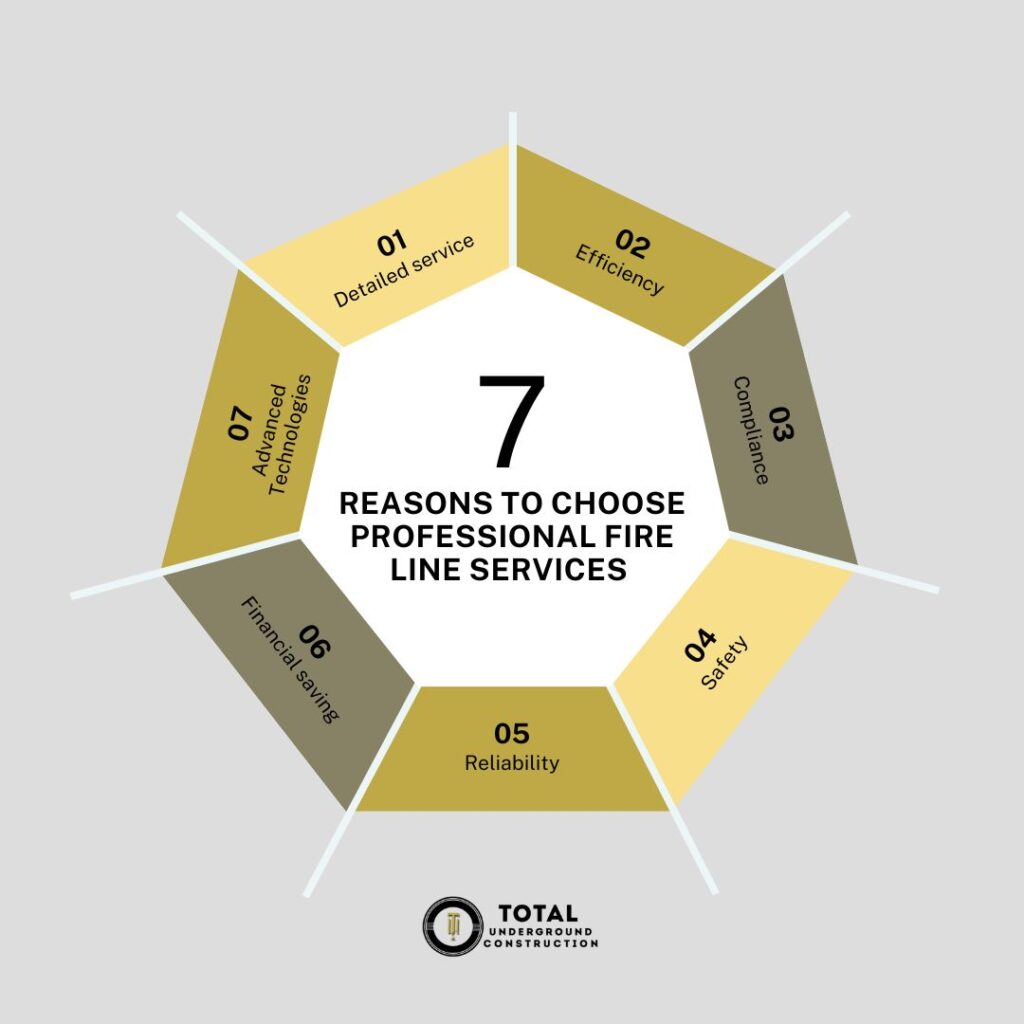

Unique Insights: Why Choose Professional Fire Line Services

Working with professional fire line services offers various benefits, especially in installation and maintenance. Here are the ones that stand out.

1. Detailed service

Fire protection service providers offer numerous services, from professional fire line installation to inspections and maintenance. Fire safety engineers also design the fire safety systems and perform thorough preliminary assessments, which involve examining your building layout to ensure every detail checks the boxes. Doing all these can be a tall order without experience or sufficient workforce.

2. Efficiency

Professional fire line services ensure minimal downtime and disruption, which translates to efficiency. The experts handle the fire line-related services as you focus on other duties that call for your attention more. Their expert knowledge allows them to work swiftly and effectively.

3. Compliance

Certified fire line experts comply with the local building codes and fire safety standards. They understand local regulations that impact the design choices. For instance, fire protection experts prioritize evacuation route design (which involves creating safe zones to serve as a refuge during fire breakouts and compartmentation design (which encompasses creating compartments for stopping fire spread).

4. Safety

Professional fire line services apply their expertise to protect your building from fire damage and prevent injuries or possible loss of life due to fire. They have the right equipment to perform installations, repairs, and inspections safely.

5. Reliability

Expert fire line services are reliable in performance. You can count on them to prevent component malfunction, failure, and unnecessary repairs. They address issues before they worsen, and the results are impressive. Even better, they are reliable during fire emergencies as they respond promptly.

6. Financial saving

Underground fire line services save on unnecessary repair costs by minimizing property damage. They also save on costs by fixing issues early and not having to wait until they are worse. That includes performing routine maintenance and repairs of the fire line systems.

7. Advanced technologies

Fire line service providers use advanced technologies to offer fire-related solutions. That includes the following modern fire safety technology solutions:

- Digital and smart sprinkler systems that you can turn on and off remotely

- Integrated alarm systems, which integrate with the building’s management system

- Cloud-based fire alarm systems, which store fire alarm information in the cloud

- Video-based smoke-fire detectors, which employ video technology to detect smoke and potential fire

FAQs

How often should underground fire line safety systems be inspected?

Underground fire lines should be inspected at least once a year. Annual fire system tests ensure the fire lines are in perfect working condition and compliant with the local building and safety standards. The fire line inspection frequency may also be dictated by NFPA 25 standards, which govern the inspection of water-based fire protection systems.

What are the signs of a damaged fire line system?

Typical signs of fire line damage are visible leaks, low water pressure, and false alarms. You should also look for signs of visible damage, such as corroded pipes and rusty sprinkler heads. Other fire system issues are strange noise and faulty control valves.

Can underground fire lines be repaired without excavation?

Yes, underground fire lines can be repaired without excavation. Non-invasive fire system fixes include trenchless paper lining where a new pipe is fitted into an existing conduit using epoxy. Trenchless fire line repair techniques offer minimal disruption and are labor and time-saving.